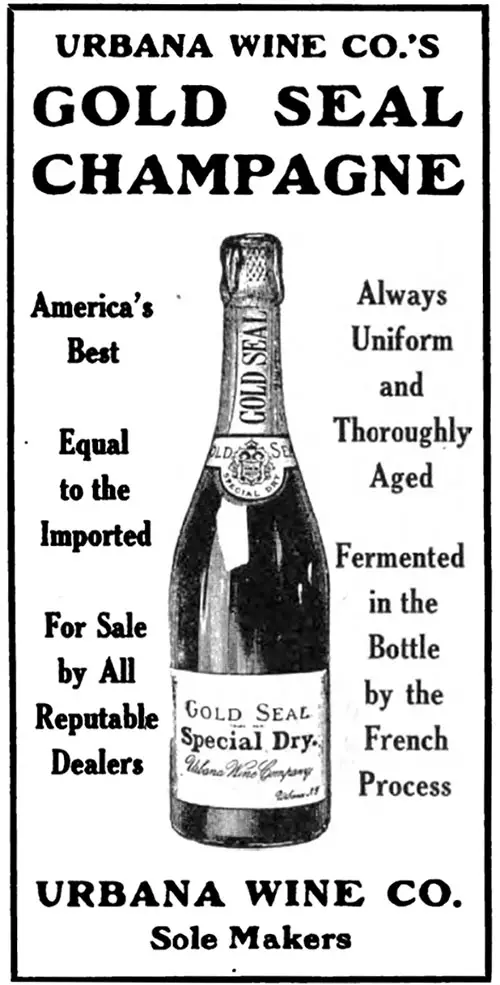

Urbana Wine Co

Urbana Wine Company's Gold Seal is the Best Natural Sparkling Wine Produced in America. Pronounced by Connoisseurs as a Superior Article for Household Consumption. They also produce a full line of well-ripened and pure Sweet Catawba, Dry Catawba, Pure Sherry, Clarets, and Brandies.

Urbana Wine Company - Gold Seal Champagne © 1907

Urbana Wine Company Story

The New Urbana Wine Company is located on Lake Keuka, a few miles from the above place, and is almost identical with that above described in point of size, capacity, kind, and quality of wines, still and sparkling.

The following description from Mr. H. W. Crabb of his cellars and plant at Oakville, Cal., represents a typical (and I might say) model California wine-grower’s establishment.

Mr. Crabb says: “My grapes are gathered in the vineyard into boxes holding about 40 pounds, and are hauled to the cellar, weighed, and emptied at a rate of 10 tons per hour into the elevator that carries them up and empties them into the crusher and stemmer.

The stems and grapes are separated by a shaft with teeth 6 inches long set spirally and running at 400 revolutions per minute over a perforated sheet-iron concave, through which pass all the skins and juice, while the stems are carried along by the spiral motion and thrown out.

The juice and skins fall into a box 14 inches long by 7 wide, with convenient openings, and with a fall of 1 foot in 10. are carried by gravitation directly into the presses or into tanks as desired.

The white grapes are generally run into tanks from the crusher and left there about twenty-four hours, when the juice is drawn off and the pomace shoveled into cars and run to the presses, situated in the center of the cellar.

After pressing, the pomace is shoveled into care and run outside of the cellar and dumped into tanks to ferment, with the addition of water, which is drawn off and distilled for brandy.

The pomace is then carted out and dumped on the ground, and is either hauled out on the vineyard or used as fuel for the steam power the next fall.

The juice or must has in the meantime been pumped into open tanks until fermentation is well started, when it is pumped into puncheons or double-headed tanks to finish.

The juice and skins of the black grape pass down the chute into open tanks to complete their fermentation on the skins, whicli generally requires from 6 to 8 days, when the wine is drawn off and pumped into tight tanks.

The pomace is pressed, carted off, and thrown on the ground along with the white. The presses have two baskets, each holding the pomace of about 5 tons of grapes and requiring about half an hour’s time each to press, with a pressure of about 300 pounds to the square inch.

While one basket is being pressed the other is being emptied anti filled. The presses are worked by a double hydraulic pump connected with the main shaft, which runs the whole length of the cellar, at one end of which is located a crusher and a stemmer to work white grapes, and at the other end are located two for crusting black grapes.

The capacity of each is 10 tons per hour. The main cellar consists of three buildings side by side, each 200 feet long by 60 wide. The second cellar stands at one end at right angles to the main cellar, and is 200 feet long by 30 feet in width, and the third cellar is 60 by 30, holding in the aggregate 800,000 gallons of cooperage.

A seventy horse-power boiler and sixteen horse-power engine are located in the distillery building 100 feet distant from the main cellar, power being transmitted by a half-inch wire cable to the main shaft.

The distillery consists of one wooden still of about 1,000 gallons capacity and one copper of about 350 gallons capacity, the former is used to make singlings which are redistilled on the copper, which: having a doubler and three water baths, produces a clean spirit of 170 to 180 strength.

This is again reduced with water to 101 for brandy. The building is 100 feet long by 60 in width. All the large cellars in the State are now- operated by the same machinery—that patented and manufactured by J. L. Heald, Crockett, Contra County, Cal. (1891)